Choose the Right Lubricant to Reduce Air Pollution

Lubricants can provide a variety of different functions within a given system. They generally are expected to decrease friction, wear and heat in machine components. One of the more overlooked aspects of a lubricant is its ability to influence environmental emissions. By selecting the proper oil, you can help to reduce some of the harmful contaminants that are spewed into the environment without sacrificing the needs of the machine or the performance of the lubricant.

Emission Factors

When you think of emissions, the first thing that often comes to mind is your personal vehicle’s exhaust pipe. These emissions add up over time and have led to laws being passed to limit the idle time of large semi-trucks. Some states even require mandatory testing of vehicle emissions, which is known as smog testing. Much of this has to do with how fuel is consumed during the combustion cycle. The more completely the fuel is burned, the fewer harmful emissions are produced.

Base Oils

While several factors can affect how lubricants impact environmental emissions, let’s start by examining the fundamental building block of a finished lubricant, the base oil. A base oil is oil without any additives. Base oils are commonly classified into three categories: mineral, vegetable and synthetic. The majority of the market share is still dominated by mineral base oils, with synthetics rapidly gaining ground. Vegetable oils are increasing in popularity but are mostly relegated to environmentally safe areas, total-loss systems and some food-processing applications. Each base oil has its own strengths and weaknesses, which will determine how much influence it has in controlling emissions.

The Traction Coefficient

One property that can improve a machine’s efficiency and lessen energy and fuel consumption is known as the traction coefficient. Consider that if you are able to decrease the amount of force required to move a load across a lubricant film, you can reduce the amount of fuel consumed and the number of emissions produced. The traction coefficient is simply the amount of force required to move a load divided by the load. The closer this ratio is to 1, the more force is required to move the load. As the ratio decreases, less force is needed to move the same load.

One property that can improve a machine’s efficiency and lessen energy and fuel consumption is known as the traction coefficient. Consider that if you are able to decrease the amount of force required to move a load across a lubricant film, you can reduce the amount of fuel consumed and the number of emissions produced. The traction coefficient is simply the amount of force required to move a load divided by the load. The closer this ratio is to 1, the more force is required to move the load. As the ratio decreases, less force is needed to move the same load.

Mineral oils by nature have millions of combinations of molecular shapes and sizes in each drop. This inconsistency in molecular size results in a higher traction coefficient. Synthetic base oils are manmade compounds and have much more consistency in several key areas, including their fluid properties and molecular size. This allows a load to move more easily across the lubricant film, thus lessening energy consumption and emissions.

To envision how this works, imagine pushing a sheet of plywood across a series of balls. If the balls are different shapes and sizes (footballs, basketballs, baseballs, etc.), moving the piece of plywood becomes more cumbersome and awkward. Now if you took that same sheet of plywood and pushed it across a series of tennis balls, with each ball the same shape and size, it becomes much easier. This is why most synthetic oils come with claims of reducing energy consumption and can actually help to decrease emissions.

Additives

Aside from base oils, additives are the other fundamental building block of a finished lubricant. Additives are blended into the base oil to impart, suppress or enhance the oil’s properties. Depending on the application, varying amounts and types of additives are added to the oil to allow it to better function in the equipment. For instance, turbine oils have a relatively small number of additives, whereas engine oil has a much higher concentration as well as more chemically aggressive additives. To reduce emissions and help your equipment

Friction-control additives leave a ductile chemical film on machine surfaces to prevent parts from sticking together and to reduce friction between the surfaces when a fluid film is not present. You likely are familiar with two types of these additives called anti-wear (AW) and extreme-pressure (EP) additives. However, a third type, known as friction modifiers, is used in most energy-conserving lubricants. These additives require less activation energy, usually in the form of heat, to become active and work in frictional zones. Simply put, they begin working at colder temperatures than traditional AW and EP additives and thus can further lower energy consumption. In engines, they also can help to decrease emissions.

Detergents serve two purposes: to clean deposits from high heat areas and to neutralize acids formed in the combustion cycle. During combustion, byproducts often get past the rings in an engine and find their way into the oil. These byproducts are referred to as blow-by. If left unchecked, blow-by will produce acids, which can result in shorter oil change intervals and poor lubrication. Detergents neutralize acids before they become a problem, thus extending the oil change interval and diminishing the risk of these acids causing further damage. As is the case with most additives, detergents are sacrificial and have limited lifespans. Typically, once detergent levels drop by 50 percent, the oil must be changed.

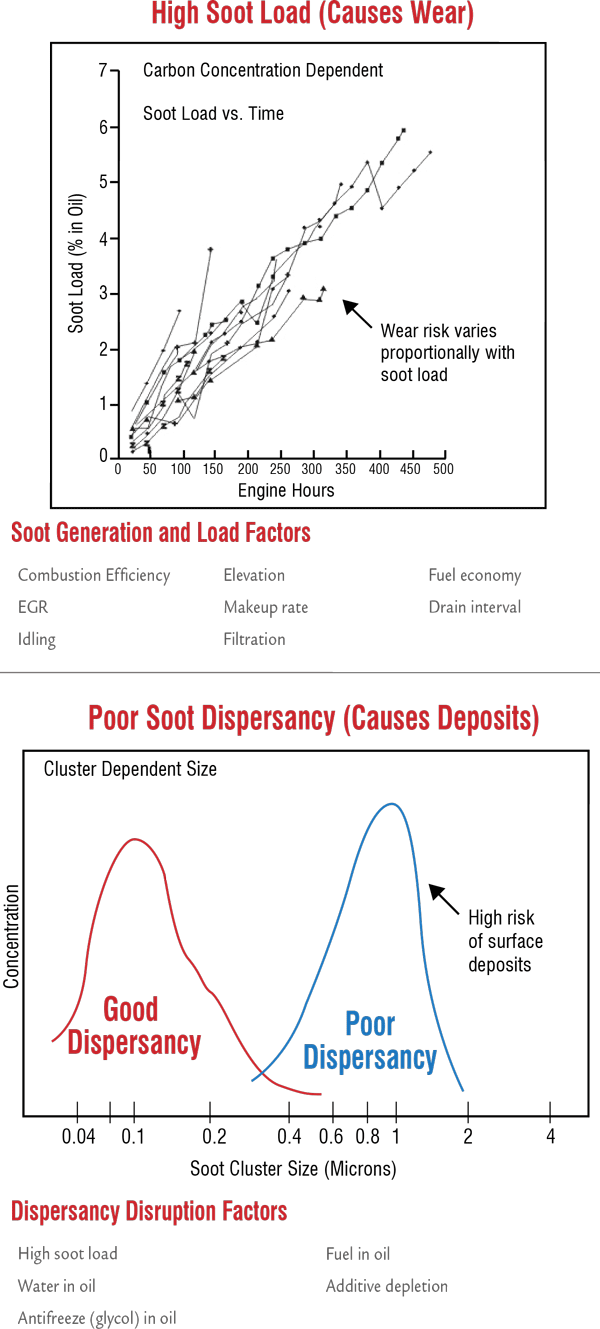

Dispersants are used to control soot deposits. Soot is a byproduct of combustion. Over time, soot can build up and lead to a rise in oil viscosity, impaired lubrication, increased wear and shorter oil change intervals. Good dispersancy is key for optimum performance and maximum lifespan from an engine. Dispersants help to prevent soot from agglomerating and settling out of the oil. If soot stays finely divided and suspended throughout the oil, you have a much better chance of filtering it and preventing the associated deposits. This can keep valves and rings free to move, minimizing emissions and acid formation.

Applications

Possibly the most important application in which emissions can be controlled with proper lubrication is the internal combustion engine. These types of engines are responsible for a large number of emissions into the atmosphere, as most people drive to work or use their vehicle for their livelihood. When purchasing motor oils, you should concern yourself with what is known as the American Petroleum Institute (API) service classification. This classification will tell you if the oil meets the standards put forth by the API in certain aspects, such as additive load, performance, emissions and fuel efficiency. For gasoline engines, the service classification begins with an “S,” such as in “SN,” which is the current classification. For diesel engines, the service classification starts with a “C,” with the most current being “CK-4.” There are formulation differences between the classifications, so it is best to know what your specific engine calls for when purchasing oil for your vehicle.

run more efficiently, you should focus on three main additive types: friction-control additives, detergents and dispersants.

Another classification found on most engine oils specifically relates to fuel efficiency. On the bottom of the API donut symbol, look for the words “energy conserving” or “resource conserving.” When you see these terms, it means this particular oil has passed the ASTM fuel economy test. In this test, oil is introduced to a test engine in which fuel economy is measured. For SAE grades 0W-20 and 5W-20, the candidate oil must show an increase in fuel economy of 2.6 percent after 16 hours of testing and 1.2 percent after 100 hours. For 0W-30 and 5W-30 grades, the candidate oil must show an increase in fuel economy of 1.9 percent after 16 hours and 0.9 percent after 100 hours. The current trend in the automotive industry is to increase fuel economy as much as possible with the use of lighter viscosity grades, better base oils and additive properties that correspond to the engine’s needs.

Perhaps the biggest issue plaguing vehicles when it comes to emissions is the formation of nitrogen oxides (NOx). When fuel combusts in an engine with the presence of air, it forms NOx. This is then pushed out the tailpipe and into the atmosphere. There are several problems associated with this, such as a higher potential for acid rain and health risks if the compound is breathed in regularly. To combat this, many diesel engine manufacturers have gone to exhaust gas recirculation (EGR) systems.

EGR systems employ the engine oil to further scrub harmful contaminants from the exhaust gases. While this is good for the environment, it can cause trouble for the engine and the engine oil if not properly managed and monitored. EGR systems work by returning some of the exhaust gases back to the engine’s intake side. During this time, the gases are cooled, which decreases the flame temperature in the combustion chamber. If the flame temperature is lowered, it helps to reduce the formation of NOx, which is better for the environment.

The problem with EGR systems is the excess soot generated due to the recycling of exhaust gas. Since soot impairs a lubricant’s health and increases the risk of engine wear, it is imperative that engines using an EGR system have condition-based oil changes. I’ve already discussed how additives can combat soot and wear, but as the soot load increases, it causes the additives in the oil to be used up faster, which results in shorter oil change intervals and a higher risk of failure. In these applications, dispersancy testing is a must.

Although most of this article has focused on engine oils, the same principles can be applied to other applications as well. Compressor systems are another type of equipment that benefits from selecting the proper base oil and additives for better handling of the gases present in the compression chamber and keeping them from being released into the atmosphere. In most refineries and petrochemical plants, compressors are utilized to recycle gases back into the process to be further refined. This cuts down on the venting of gases or flaring (burning off), which leads to environmental pollution.

Always keep in mind that by properly matching the needs of your equipment to the properties of the lubricant, you not only can extend the life of your machinery, but you can also help protect the environment in which we live.