Follow the Trend for Successful Oil Analysis

Setting cautionary and critical limits (or targets) for oil analysis results is essential and irreplaceable as groundwork in an oil analysis program. It’s what helps answer one of the most commonly asked questions: “Is the oil still good?” Nevertheless, the data changes observed, even if they are within the established limits, can still prove to be valuable. In these conditions, trending oil analysis data is where the value is gained and will help answer what might be the next question asked: “When will my oil go bad?”

If you think about it, simply obtaining a snapshot of data from an oil sample is essentially worthless without something to which to compare it. This is why trending data in oil analysis reports is so beneficial. It not only allows you to determine if the current oil properties are unfavorable but also if they will become unfavorable in the near future. Indeed, quality trending provides a powerful means of recognizing when an oil property is moving in an unhealthy or threatening direction.

The most effective way to follow a trend is to consistently collect representative oil samples and track the data from the results by plotting them on a property-versus-time graph. The “property” can be anything from the remaining additives within the oil to the base oil’s changing properties or the number and types of particles.

| Human Population Growth | Particle Coontamination Growth | |

|---|---|---|

| Site of Growth | Earth | Lubricated machine |

| Variables Enhancing Growth | Modern medicine, Industrial Revolution, technology, migration | Lack of wear protection, misalignment, improper ventilation and filtration control |

| Variables Suppressing Growth | Disease/plagues, war, natural disasters | Proper lubrication, quality machine design, proper ventilation and filtration control |

| Result of Extreme | Population To be determined | Machine failure |

It is imperative that oil samples are carefully collected and that all variables are minimized or at least addressed. Among the factors that can influence the results include sample location consistency, service life of the machine and oil, makeup oil rates, changes in environmental or operating conditions, oil formulation changes, testing procedure consistency, etc.

The key to success with trending is to learn from the past. This includes others’ past failures, not just those of your machines. Start by identifying when certain oil properties have typically been healthy and use this as the standard. Also, take note of when a change in an oil property has previously led to a machine issue or failure. You must develop the awareness to recognize when a change in a particular property could eventually lead to a problem with the machine.

Quality trending provides a powerful means of recognizing when an oil property is moving in an unhealthy or threatening direction.

Looking Back at the Past

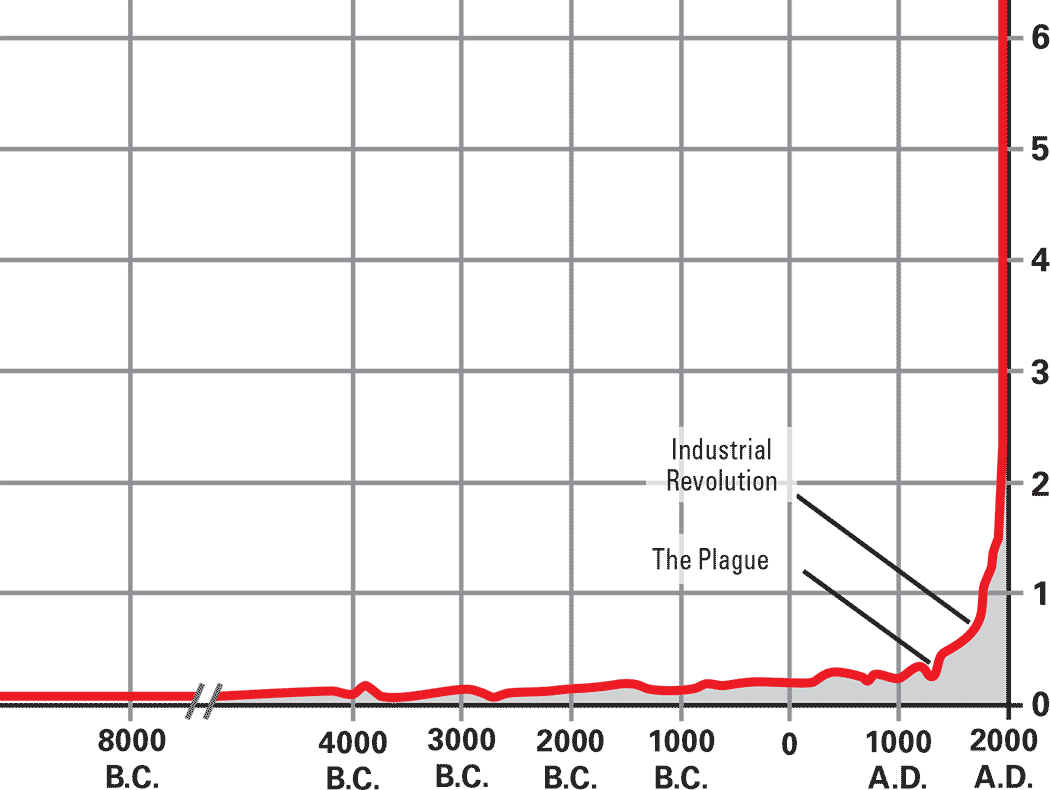

The world’s population growth offers a good example of the types of trends that can exist within machinery. The earth’s population has been growing for thousands of years, but it wasn’t until around 1800 that it reached 1 billion people. While this was a major milestone, it only took approximately 120 more years to double to 2 billion. Less than 100 years later, the population is rapidly approaching 8 billion people. Many factors have influenced this recent trend, such as the Industrial Revolution and advanced medicine. Figure 1 shows how this rise in population would appear on a graph.

This trend can be compared to the growth of particle contamination in machinery. Particles produce particles. In fact, one particle can generate as many as 20 new particles within a machine. Of course, this will depend on many variables, such as particle ingression rates, the filtration rate, the likelihood of wear generation, etc. Regardless, when particles are the instigator of new particles being created, the contamination can quickly escalate.

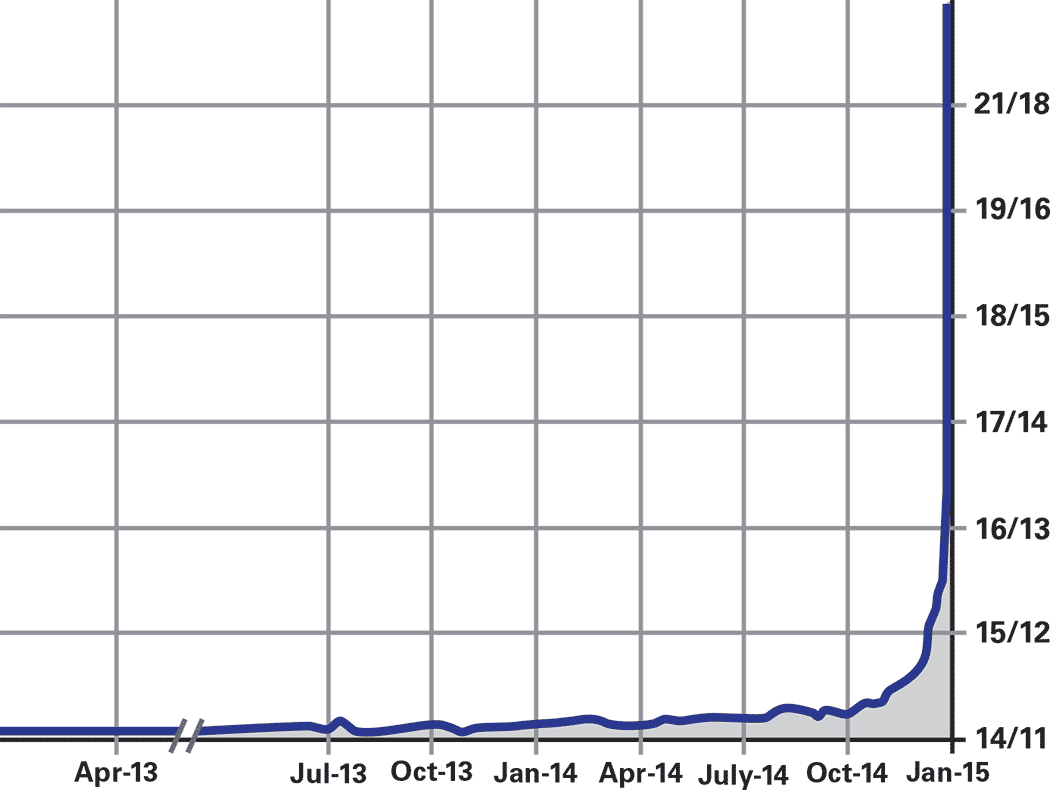

By adding quarterly sampling dates and ISO particle contamination codes to Figure 1, we can illustrate a lubricated machine that was accidentally introduced to new contaminants and resulted in increased wear generation. Note the dramatic trend toward the most recent dates in Figure 2. When this type of growth in particle concentration occurs, it will be linked to an imminent machine failure.

In order to predict an impending rapid growth of particle contamination, oil sampling must be performed frequently enough to detect a slight uncharacteristic increase. For example, in Figure 1, if the world population is measured every 1,000 years, the results would be 0.1 billion, 0.1 billion, 0.1 billion, 0.2 billion, 0.2 billion and finally 7 billion. However, if the population is measured twice as frequently or more, it would be much easier to recognize the start of the abnormal increase. Sampling machines for changing oil conditions is no different.