The Modern Art of Lubricating Mining Equipment

Surface mining is a very old practice in North America. For example, mining for copper at the surface of the Michigan Upper Peninsula appears to have started as early as 5000 B.C. The ore produced through the hard labor of thousands of miners went to the manufacture of hand tools and jewelry. It is estimated by scientists and engineers that given the tools available at the time, it would have taken 10,000 people approximately 1,000 years to excavate the 1.5 billion pounds of ore from this area of Michigan.1

In contrast, it would take approximately 38.5 hours for the fabled Big Muskie dragline to excavate the same amount of material. Perhaps if the Chippewa had the Big Muskie on hand they would not have given up the 30,000 square miles of the Upper Peninsula, with its high-quality copper from Lake Superior.

Talk of surface mining conjures visions of panning in a river during the California gold rush period in 1849. Since that time, North Americans have seen tremendous changes in many areas of life, not the least of which is the surface mining industry. Mining equipment has evolved into some of the most fascinating functional mechanical structures known to man.

As a case in point, take a look at this Bucyrus Class 24, (Figure 1), currently being restored at Reynolds Alberta Museum, located in Wetaskiwin, Alberta, Canada. This steam-powered dragline, erected in 1917, utilized a 100-foot boom with a four-yard bucket. By comparison, a modern standard size pick-up truck offers about 2.5 cubic yards of space. To move it from one location to another, timbers were placed under the tub and the operator would use the bucket to pull the machine over the timbers to the desired location.

From this primitive beginning, mining tools have evolved into massive machines. Rock drills, front-end loaders, electric cable and hydraulic shovels - some boasting bucket sizes in excess of 50 yards - and mammoth trucks and draglines, such as the Bucyrus International, Inc. 2570WS (Figure 2), have introduced unprecedented levels of productivity for equipment owners and unprecedented challenges for the maintenance staffs. Greatly increased component sizes and load limits have placed tremendous responsibility on the machinery designer and the lubricant system manufacturer, to design and engineer systems that can be counted on to effectively lubricate and sustain these machines.

These machines are often as large as houses, with some booms extending nearly 300 feet. Depending on the type of machine, whether it is a shovel or a dragline or a drill, the machine’s key components may be either electrohydraulic or electromechanical. For instance, the P&H 4100XPB shovel (Figure 3) is driven solely by electric motors (no diesel engines) to turn the cab and operate the lift, while the Komatsu Demag Model H655S (Figure 4) employs state-of-the-art electrohydraulic systems. Some draglines have huge hydraulic systems and electrically driven gears, with sump capacities into the thousands of gallons. The rolling stock, including bulldozers and large haul trucks, are powered by diesel engines. Many of the loading and hauling equipment designs incorporate hydraulic systems powered by diesel generators.

As one might expect, effective lubrication of these heavily loaded components is absolutely critical to efficient, reliable, economical operation of a mine site. As the machines have grown in size and sophistication, the manufacturers of lubricant products and delivery systems have had to work equally hard to match the new requirements.

As one might expect, effective lubrication of these heavily loaded components is absolutely critical to efficient, reliable, economical operation of a mine site. As the machines have grown in size and sophistication, the manufacturers of lubricant products and delivery systems have had to work equally hard to match the new requirements.

There are two equally important aspects of lubrication effectiveness in the strip mine: the delivery system and the lubricant.

Lubrication Systems

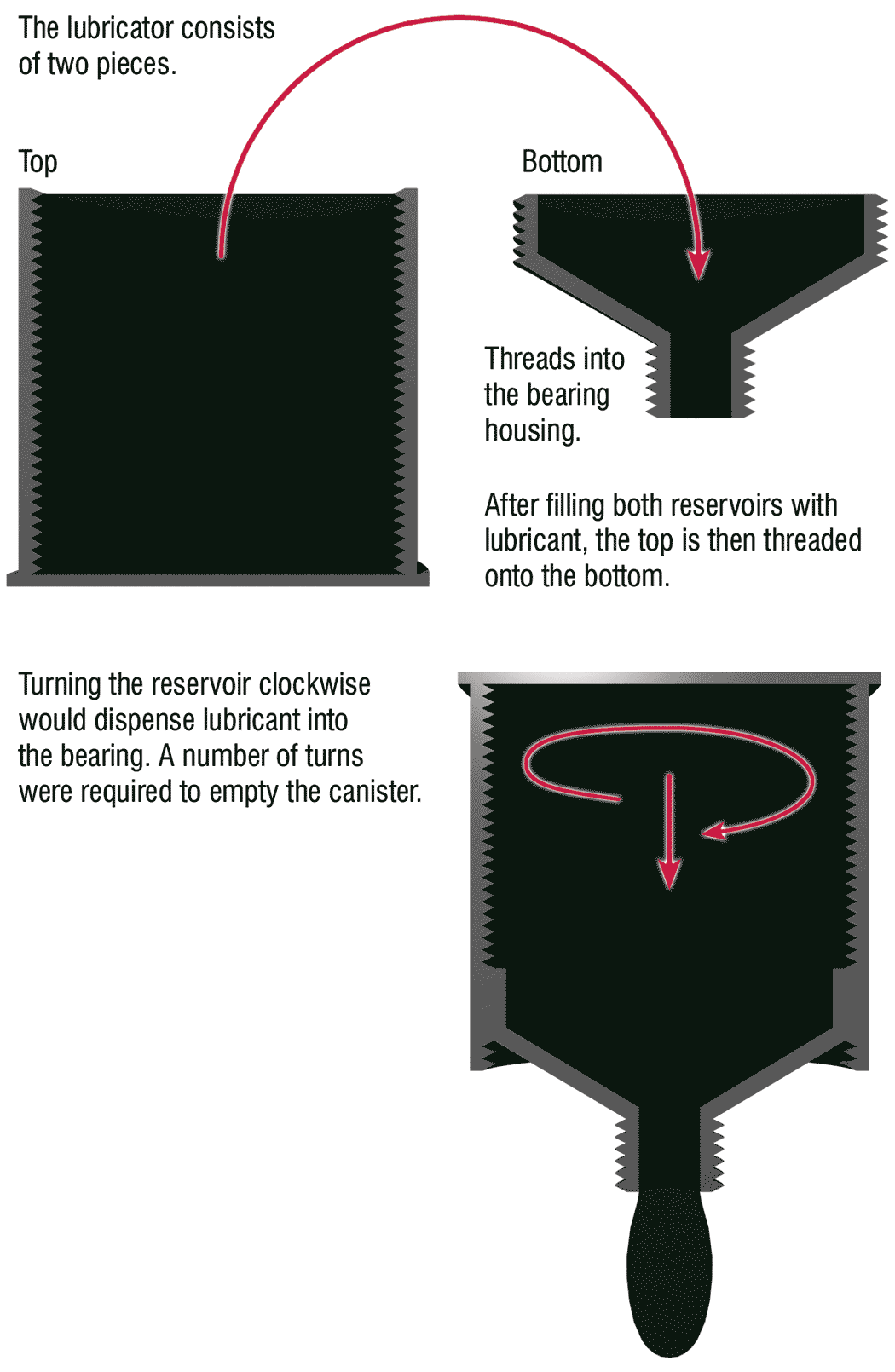

Lubrication distribution systems have improved greatly over the years. Figure 5 is a reasonable facsimile of what would have been used on the Bucyrus 24 dragline in the early 1900s. The lower funnel-shaped half of the unit would be threaded into a port in the bearing housing. The upper cylinder-shaped half would be full of multipurpose grease (MPG).

Lubrication distribution systems have improved greatly over the years. Figure 5 is a reasonable facsimile of what would have been used on the Bucyrus 24 dragline in the early 1900s. The lower funnel-shaped half of the unit would be threaded into a port in the bearing housing. The upper cylinder-shaped half would be full of multipurpose grease (MPG).

Turning the upper cylinder clockwise would lower the cylinder onto the funnel-shaped portion, forcing (extruding) the lubricant stored in the reservoir of the cylinder portion through the funnel into the bearing. The lube tech would make routine lubrication checks throughout the machine. As required, these lubricators would be turned to ensure the lubricated components received adequate replenishment while in use.

The Lube Systems of Today

Today’s centralized lubrication systems factory-installed on mining machinery have greatly minimized the need for lube techs in most cases. These computerized systems are now capable of dispensing the right product, in the right amount, to the right point, and at the right time.

There are a number of centralized lubrication system manufacturers that offer a wide range of system types and designs to meet the needs of practically any mining application.

Most lubrication systems consist of a grease pump, a motor to drive that pump and some sort of injector or valve to control or measure lubricant volume. Most utilize a programmable logic controller (PLC) to program the frequency of the lubrication replenishment cycle. As sophisticated as some of these systems are, maintenance and proper set-up is essential to ensure that their benefits are realized.

Upgrading

With the advancements in centralized lubrication systems, serious consideration should be taken when selecting a system or upgrading an existing system. Although the system’s operation is generally quite simple and effective, performance limitations can have detrimental effects to lubricated components, such as the impact of changing lubricant viscosity. If a lubrication system is modified to accommodate more lube points or there is a need to change a lubricant product, it is strongly recommended that both the system manufacturer and lubricant manufacturer be consulted before such changes are made.

Lubricants

Lubricant manufacturers have continued to improve their products to meet the needs of bigger, faster machines. Although most lubricant suppliers are not lubrication system specialists, many have the resources to provide technical support, offering sound advice for selecting the products best-suited for the applications.

The products commonly used in mining equipment can be divided into three groups: heavy-duty lubricating oils, such as EP oils for enclosed gear drives; multipurpose engine, circulating and hydraulic oils for engine, bearing lubrication and fluid power; and general purpose grease, for normal industrial bearing applications and specialized mining products.

Walking draglines may require lubricants for the very large plain bearings that support the entire frame of the unit as it moves through the walking process. These lubricants may have a high concentration of lubricating solids or soft metals dispersed into a stiff grease and delivered in small bags (for the walking mechanism without an automatic delivery system) just ahead of the peak loading area. This grease is referred to as a Walking Cam lubricant.

An effort to reduce the number of lubricants on a machine has driven the development of multipurpose products designed to meet several different applications from a single lubrication system. The various components to be lubricated may include the open gears, guide rails, main table bearings and various smaller slides and bearings. This presents a variety of challenges to tackle with one or two products. Specialty product manufacturers strive to meet the wide range of challenges with a single product.

Despite the large volumes involved in filling a dragline during a lubricant change, given the product sophistication, some of these products may cost as much as $2.50 per pound. Management of the lubricant consumption to control costs becomes an integral part of the sourcing process.

Lubricant Management - Supply and Delivery

Vendors offer various options for purchase and delivery of these products, ranging from simply purchasing and managing the distribution of lubricants throughout the mine site, to programs offering on-board delivery, lubrication system set-up and long-term maintenance.

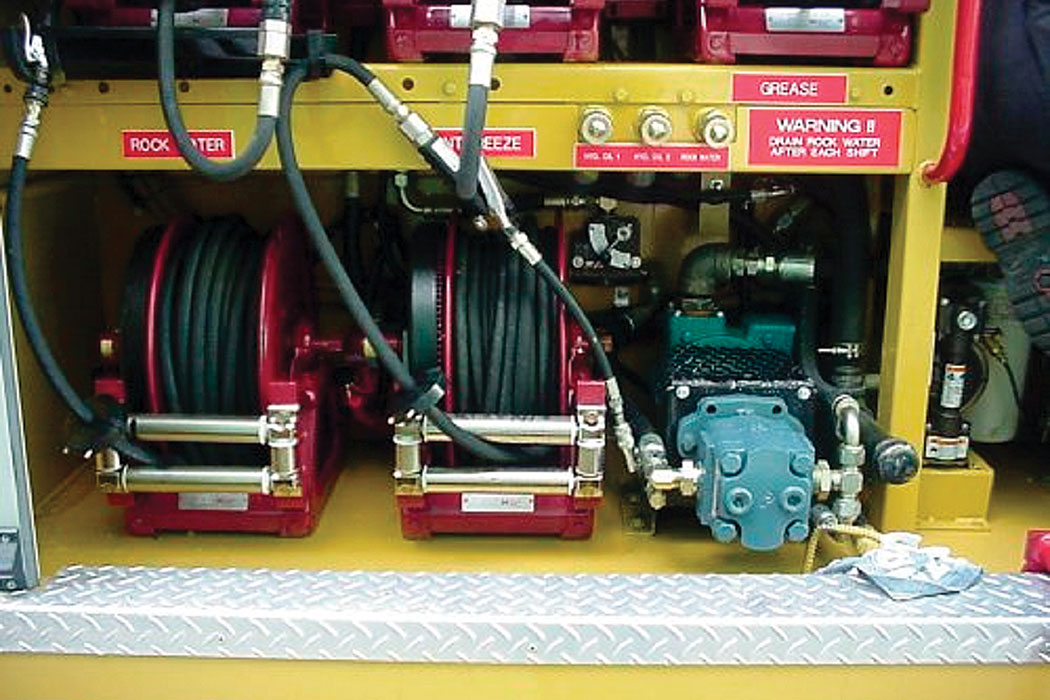

Vendors may use several methods of delivery and replenishing lubrication systems and reservoirs. Today’s service equipment, like the delivery truck in Figure 6, is designed to meet the exacting mine delivery requirements. This may include a system of nozzles and hoses piped through filters for each type of lubricant as well as the necessary drive train to assure that the loaded vehicle can get out to the equipment under the worst of driving conditions.

As with any industrial lubrication application, cleanliness must be first and foremost. Contaminated lubricants will dramatically reduce the life of the lubrication system components as well as the lubricated components. The dispensing equipment installed on the truck offers a completely self-contained, clean storage delivery environment, which helps to reduce the risk of contamination for all of the products that are delivered to the equipment.

Full-Service Supply Programs

Product-service combinations have been around the industry for years. Initially offered by specialty lubricant manufacturers, product-service combinations have proved valuable. Most lubricant manufacturers now offer some kind of service supporting their products. The ownership of full-service lubrication programs is completely taken over by the vendor, sometimes with the complete offering being purchased on a cost-per-hour program. Because many lubricant vendors resist consigning products to a mine, the cost-per-hour contract offers the next best option. The purchase of the product is based on the hours of machinery operation. Sometimes these supply programs are provided to mines in conjunction with other full-service offerings. While this may sound ideal, vendors typically profit from selling less lubricant. Therefore, caution should be exercised when choosing this type of program-vendor combination.

For the simple cost of this combination, the mines should receive a prenegotiated amount of monthly service along with the product. The service cost would be bundled into the cost of product. These programs are advantageous to all when negotiated properly. As long as the level of service doesn’t decline over the term of the contract, the benefits of the product-service combination can be considerable.

Lubrication Services Specialists

More recently, independent lubrication service consultants are becoming a viable alternative to the industry. Utilizing an independent consultant offers a mine the ability to purchase the product of choice based strictly on quality and product cost, but without any possible hidden costs of product-service combinations or cost-per-hour contracts. The operators purchase the lube products for the equipment based on equipment criteria and purchase the service of a consultant based on experience and costs. This platform is a unique and upfront approach to product-service combinations. When considering an independent lubrication service consultant, check the individual’s references supporting his/her abilities and knowledge.

As the industry continues to evolve, expect to see continued evolution in all aspects of the industry and allied fields. With global positioning satellites (GPS) offering the potential for remotely operated equipment, computer systems taking lubrication systems to new levels of control, manufacturers continuing to meet the demands of an ever-changing and competitive industry, one thing should always remain the same. When it comes to the development and application of lubricating products, providing the cleanest possible environment, storing the products properly, reducing rehandling and applying the right product - in the right amount, in the right place, at the right time - will always be the necessary criteria, no matter how many times these practices are reinvented.

Editor’s Note

For an interesting pictorial trip through the task of moving a big stripping shovel, go to www.stripmine.org/spdeup01.htm. A high-speed connection is recommended for the number of pictures in the story.

Photos courtesy of Bucyrus International, Inc., P&H Mining, Komatsu Demag and Lubrication Management Systems, Inc.