India “Mining Sector” Stats

The GDP contribution of the mining industry varies from 2.2% to 2.5% only but going by the GDP of the total industrial sector it contributes around 10% to 11%. Even mining done on small scale contributes 6% to the entire cost of mineral production. Indian mining industry provides job opportunities to around 700,000 individuals.

Particulars

- 1st in production of Mica blocks and Mica splitting

- 3rd in Iron & Steel production

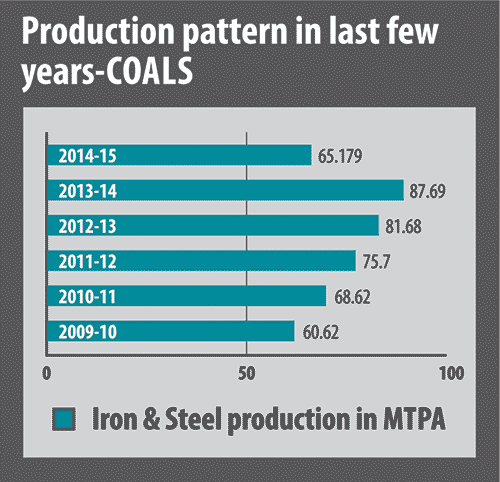

- 3rd in the production of Coal & Lignite, Barites and Chromites

- 6th in Bauxite and Manganese ore

- 10th in Aluminums

- 11th in Crude Steel.

- 89 minerals

- 4 fuel minerals

- 11 metallic

- 52 non-metallic

- 22 minor minerals

Major Minerals Production in FY2014 & FY2015

| Minerals | Measure (MT) | |

|---|---|---|

| FY14 | FY15 | |

| Coal | 563.09 | 541.18 |

| Lignite | 44.29 | 43.37 |

| Natural Gas (Utilized) | 34412 MCM | 32693 MCM |

| Petroleum (Crude) | 37.78 | 37.41 |

| Bauxite | 21.666 | 20.201 |

| Chromites | 2.852 | 1.681 |

| Copper Concentrates | 0.139 | 0.112 |

| Gold | 1564 Kg | 1322 Kg |

| Iron Ore | 152.4 | 129.1 |

| Manganese Ore | 2.588 | 2.166 |

| Zinc | 1.490 | 1.318 |

| Lead Concentrates | 0.178 | 0.194 |

Equipment In Industry

Construction and mining equipment cover a variety of machinery such as hydraulic excavators, wheel loaders, backhoe loaders, bull dozers, dump trucks, tippers, graders, pavers, asphalt drum / wet mix plants, breakers, vibratory compactors, cranes, forklifts, dozers, off-highway dumpers (20T to 170T), drills, scrapers, motor graders, rope shovels etc. They perform a variety of functions like preparation of ground, excavation, haulage of material, dumping/laying in specified manner, material handling, road construction etc. These equipments are required for both construction and mining activity.

Lubrication In Mining & Equipments

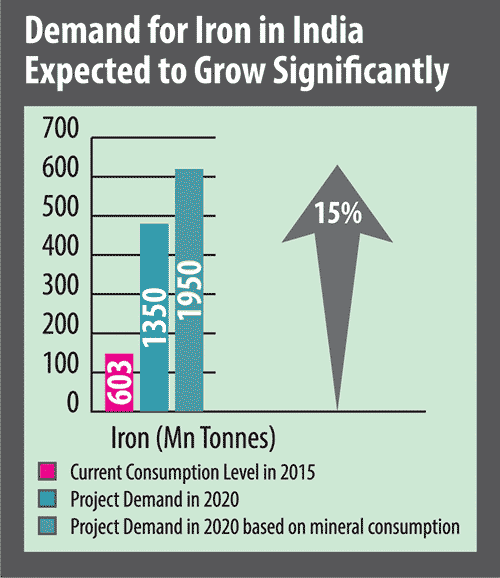

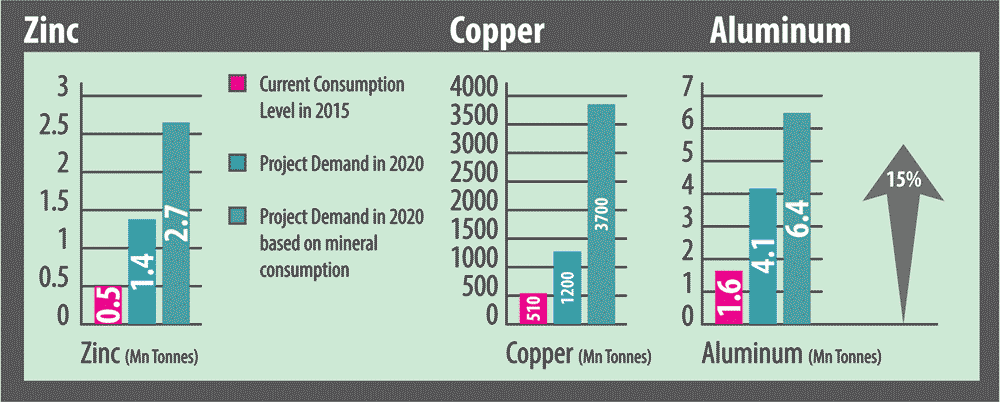

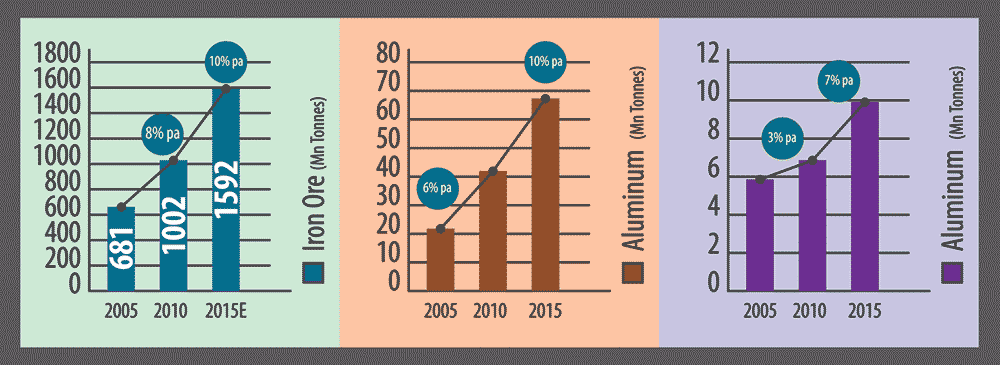

Statistically every single tone of metal produced creates the demand of 1 million lire of lubricant oil. The market for lubricant product in country is estimated at 2.2 billion litres annually.

mechanical loads cumulatively result in a high wear rate of bearings and friction points. Lubrication is therefore absolutely necessary in order to provide the right protection.

- Moisture and particles – combined with heavy loads, shock loads, extreme pressures and continuous operation – create a difficult job for any lubricant.

- Mining gearboxes tend to be overloaded, which leads to overheating and excessive wear. This often results in premature failure of the gears. Other common mechanical issues include emulsification of the gear oil due to water contamination and extreme foaming.

Most wire ropes are lubricated during the wire rope manufacturing process, but the lubricant will not last the life of the rope. When looking for a wire rope lubricant, we should choose a lubricant that contains no acids or alkalis, possesses the adhesive strength to stay on the rope, penetrates between wires and strands, has high fluid film strength, resists oxidation, and remains pliable. It is important to remember that most wire ropes fail from the inside out. Proper lubrication will help prevent deterioration of wire rope due to rust and corrosion.

| Construction Equipment | Mining Equipment |

|---|---|

| Backhoe Loaders | Motor Graders (above 200 HP) |

| Crawler Dozers upto 320 HP | Dozers (above 320 HP) |

| Crawler Excavators above 3.5 Cu.M. | Hydraulic Excavators (65 T and above) |

| Loaders | Rope Shovels |

| Motor Graders (below 200 HP) | Drag Lines |

| Skid Steer Loaders | Drills |

| Wheel Loaders (below 3 Cu.M.) | Wheel Loaders (above 3 Cu.M.) |

| Vibratory Compactors | Surface Miners |

| Dump Trucks (below 35 T) | Off Highway Dumpers (above 35 T) |

| Tippers topic | Continuous Miners |

| Road Milling Machines | Long Wall Equipment |

| Asphalt Pavers | Batching Plants |

| Asphalt Drum / Wet Mix Plants | |

| Fork Lifts | |

| Tower Cranes | |

| Mobile Cranes – Pick & Carry | |

| Mobile Cranes 360o slew | |

| Transit Mixers |

| Sl. No. | Equipments | Lube Points |

|---|---|---|

| 1 | Excavator | Diesel Engine |

| Hydraulic System | ||

| Pump Transmission | ||

| Swing Device | ||

| Swing Bearing Gear | ||

| Final Drive Gear Box | ||

| Splitter Gear Box | ||

| 2 | Dozzer | Final drive |

| Diesel engine | ||

| Hydraulic System | ||

| Power Transmission | ||

| Pivote Bearing | ||

| Telescope Suspension | ||

| 3 | Drilling Machine | Diesel engine |

| Hydraulic System | ||

| Air Compressor | ||

| Feed Gear Box | ||

| Hydraulic Hammer | ||

| Rotation Gear Box | ||

| 4 | Dumper | Diesel engine |

| Hydraulic System | ||

| Power Transmission | ||

| Final Drive Gear Box | ||

| Final Drive Differential Gear Box |

| Equipment | Lubricants Used |

|---|---|

| Large Mobile Equipment Like Dumper | Engine Oils, Hydraulic Oils, Transmissions Fluids, Automotive, Gear Oils |

| Lorries, Dozers, Excavators, Back Hoe | Greases, Brake Fluids, Radiator, Coolants, High Pressure Pin Greasing |

| Rock Drills | Rock Drill Oils, Hydraulic Oils, Semifluid Greases |

| Conveyor Belts (Gear Boxes, Head, Tail And Tension Bearings, Hydraulic System) | Gear Box Oils, Roller Bearing Grease |

| Compressors | Hydraulic Oils, Compressor Oil (Reciprocating And Screw)-Can Be Synthetic Or Mineral |

| Pneumatic System | Air Line Lubricant (Pneumatic) Multi-Purpose, EP Type And Graphite Or Molybdenum Disulphide Grease For Anti Seize Of Threading In Drilling Rods. |

| All Grease Points | Anti Seize Of Threading In Drilling Rods. |