Machine Modifications That Increase Reliability

The ultimate goal of lubrication excellence is to increase machine reliability and reduce operating costs. To achieve this objective, changes must be made at different levels of the plant, including the technology and hardware that are currently in use.

Machines may require modifications for a variety of reasons, such as to improve the accuracy of lubrication procedures, to enable inspections of the in-service oil and the machinery, to ensure precise oil analysis and consistent oil sampling, and to enhance the effectiveness of the contamination control program. Following is an overview of these types of modifications.

Lubrication Procedures

It is critical that machines receive the right lubricant in the right amount at the right frequency. It is also essential that they are lubricated using clean, ergonomic and safe procedures. To ensure proper lubrication practices, machines must have the appropriate accessories installed. This typically involves lubricant-delivery devices like constant-level oilers, single-point lubricators, grease fittings, grease purge valves, centralized lube systems, spray systems, etc. Temperature-management systems, including heaters and coolers, may also be needed, along with rolling-element bearing seals and shields, and power-flush quick-connects on reservoirs and sumps.

Inspections

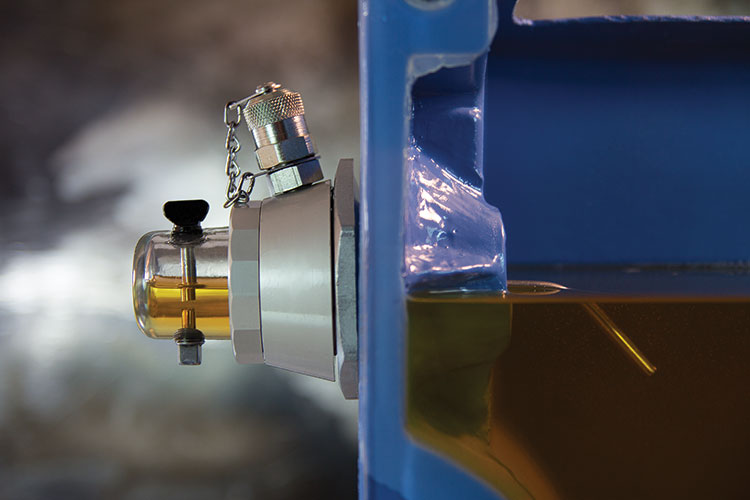

Oil analysis that is supported by visual inspections of the in-service oil offers a powerful way to monitor the condition of the oil and the machine. Simple visual inspections can confirm that the oil is in good condition or indicate the presence of contaminants or excessive degradation. Among the devices that may be installed to facilitate inspections of the oil include bottom sediment and water (BS&W) bowls, which enable quick inspection of low-lying contaminants and sludge, and level gauges, which should be located near fill ports and be large enough to easily determine the oil level.

From time to time, machines should be inspected internally to verify that the lubrication system and machine components are free of deposits and excessive wear. External inspections are also useful to identify the presence of leaks or abnormal operating conditions. A number of machine modifications or accessories can be employed for this purpose. For instance, large reservoirs and sumps should be equipped with inspection hatches. These hatches, which can be opened for a visual inspection and then sealed again, should incorporate lips, gaskets and compression clamps/bolts to control accidental dirt entry, ingression and air movement. Magnetic drain plugs and other inspection devices enable wear metals to be examined and removed from the oil. External modifications can allow for visual inspections of lube points, chains, couplings, belts, etc. Minor hatches or plugs may also be removed to introduce a camera or borescope.

Oil Analysis

Oil sampling is key to the success of an oil analysis program. Oil samples obtained incorrectly will produce faulty technical reports and an inaccurate machine diagnosis. An example of a machine modification for proper oil sampling would be installing a primary sampling port. These ports should be positioned according to the lubrication system’s configuration. Secondary sampling ports can also be useful for monitoring specific components.

Installation of in-line instrumentation will be necessary for real-time lubricant monitoring in large or critical machines. These types of sensors include fluid pressure gauges, flow meters, temperature gauges, free water alarms, low oil level alarms, pressure differential gauges, filter bypass alarms, air-intake vacuum gauges, etc.

Installation of in-line instrumentation will be necessary for real-time lubricant monitoring in large or critical machines. These types of sensors include fluid pressure gauges, flow meters, temperature gauges, free water alarms, low oil level alarms, pressure differential gauges, filter bypass alarms, air-intake vacuum gauges, etc.

Contamination Control

A well-structured contamination control program is a strategic element of proactive maintenance. It addresses and helps to eliminate the root causes of critical machine failure modes. A wide range of machine modifications can be made to enhance contamination exclusion and removal, such as incorporating circulating systems with quality oil filters, high-performance breathers, hydraulic cylinders equipped with rod boots to control ingression, reservoirs designed with baffling to enable contaminants to settle or detrain, and return-line diffusers to control tank aeration. Other alternatives would be to install dust protection covers where grease fittings are used and offline filters on bath-/splash-lubricated machines. You may also need to use headspace management equipment with large reservoirs.

Retrofitting machines is a smart strategy for reducing operating costs. It will require full support from management and an allocation of resources, but the return should be several times the investment. Of course, before any equipment modifications are made, it is necessary to assess each machine based on its criticality and operating conditions. Safety and ergonomics must also be considered. While this may take some time, it will pay off in the long run with increased machine reliability.