Five Common Mistakes Made when Developing an Inspection Route

Developing and implementing inspection routes is a key part of a successful lubrication program. Inspection routes are complex, and the reality is that just because they are being performed doesn’t mean they are being performed correctly. Let’s look at an example:

Developing and implementing inspection routes is a key part of a successful lubrication program. Inspection routes are complex, and the reality is that just because they are being performed doesn’t mean they are being performed correctly. Let’s look at an example:

Larry Smith is a lube tech. He has a few years of experience in this role but no formal training. His inspection route for today includes 64 machines spread throughout four different areas of the plant - a task that should take Larry four to six hours to complete. Larry is given simple instructions to “inspect”; it is also assumed that he will take corrective actions when needed.

At each inspection, Larry relies on his intuition. He looks at sight glasses (where available) to determine the oil level, and when necessary, he tops up the oil. He also looks for abnormal conditions, fixing the things he can (like a hatch left open), and noting unusual conditions that he can’t address immediately (spent breathers, loose bolts on machine footing, leaky drain ports, gauge issues, etc.). Many of the machines that Larry inspects are not equipped with sight glasses, greatly limiting the scope of Larry’s inspection abilities and leaving him only able to make general observations.

How does Larry’s inspection route compare to your inspection routes? Are you relying on your intuition and experience alone to know what to look for? Do your machines lack the hardware to allow for good inspections? Here are some mistakes that, when fixed, will greatly improve the effectiveness of Larry’s work:

5 Common Mistakes Made When Developing an Inspection Route

1. Not Giving Inspections Enough Importance

1. Not Giving Inspections Enough Importance

Unlike other condition monitoring techniques that have quality training, certificates and tools, inspection routes are seen as inherently straightforward, often leaving lube techs with only a vague understanding of what they should be doing. This is a mistake; human-sensory inspections have a lot of value. With the right training and collection devices, each person who walks by a machine, whether they’re a lube tech or not, will have an opportunity for a quick inspection.

2. Not Collecting the Data

2. Not Collecting the Data

Larry’s inspection route was filled with reportable conditions; some of them were even noticeable without formal knowledge or training. He made corrective actions where possible and documented some of his findings. Unfortunately, however, the only place he was able to document these findings was in the “notes” section of the inspection document - which Larry’s supervisor will likely overlook or not fully understand.

This is a common mistake with inspection routes because this data is easily lost in the endless tasks that must be completed. For inspection routes to be consistently successful, a systematic method of documenting and cataloguing reports must be created. With visual observations, it’s incredibly valuable to collect the data with pictures or videos as well. A simple comparison to a previous photo can quickly determine the rate at which conditions change. And with mobile phones acting as inspection collection tools (such as LubePMTM), this can be done much more easily than in the past. When everything is tracked and records are accessible, follow-up actions are more likely to occur.

3. Not Modifying Machines

3. Not Modifying Machines

As mentioned, only some of the machines that Larry inspects are outfitted with sight glasses. The effectiveness of an inspection route is only as good as the individual inspections themselves. Visual accessibility is important to understand internal oil and machine conditions. If a critical gearbox, for example, is completely sealed up on all the ports with a simple OEM-provided vent plug or has an impossible-to-access sight glass (such as against a back wall), there is very little that Larry can inspect during typical operation. One of the most common mistakes for inspection rounds is not preparing the machines correctly. Unlike other condition monitoring techniques, where special tools are often necessary, and lots of skills and experience are needed, inspections don’t require much. But what they do require (sight glasses) is very important to get right.

4. Not Training and Cross-training

4. Not Training and Cross-training

As mentioned, inspections are often perceived as straightforward, lacking sophisticated training or tools, but there is much that goes unnoticed to the untrained eye. Everything else may already be fully in place (people, tools and machine modifications), yet the inspections are still lacking because of gaps in the inspector’s knowledge - gaps that Larry is unaware of. Luckily, this can easily be fixed through training. One great practice is cross-training the experience each person may have. This can be done by bringing a team of personnel together around the plant and spending 10-20 minutes at each machine, letting each person talk about what they see and what it could mean. Each person has different experiences, based on certain equipment in their area or based on previous facilities where they have worked. This shared knowledge is critical for improving inspections and creating a healthy culture with a common goal. This is enhanced further by bringing in a professional trainer on inspections or similar personnel from other plants within the same corporation.

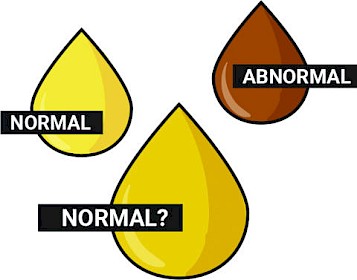

5. Not Defining Normal vs. Abnormal

5. Not Defining Normal vs. Abnormal

Larry may not be aware that a particular colour or clarity change in the oil (as observed through a sight glass) is considered abnormal. Some oil colour is expected, but how dark? What about other unusual haziness observed? Any condition monitoring or testing, when done correctly, trends data and compares it against a baseline (this is necessary). Inspections are no different. A good example of a well-defined abnormal condition is the colour gauge sticker on a desiccant breather. But not every inspectable condition is as simple to illustrate as a change in colour. Yet, some abnormal definitions need to be well defined so that Larry can be confident in his role as an inspector and take the right corrective actions when necessary.