Implementing a Training Plan to Support a World-class Lubrication Program

Through the years, Noria has seen many cases in which world-class lubrication practices were implemented successfully as well as unsuccessfully. One of the key factors in determining the success or failure of such an implementation is the training/education of the team. Of course, not all project managers have experience assessing skills and competencies needed for a job. Consequently, they may not have the expertise to tailor a training plan specifically for the maintenance team and other functions involved in the lubrication program implementation.

To be effective, a learning program must be delivered in conjunction with other resources that will allow individuals to absorb this new knowledge and introduce new behaviors into their daily work. These additional resources should include the tools that will make the work more productive, such as new technologies like ultrasound, sampling devices and hardware, a quality lube room, equipment modifications, top-up containers, etc. The methodology should also be provided. This refers to the instructions, work orders, software, etc., that will guide personnel to follow the proper procedures at the appropriate time. Failure to deliver these resources could put the effectiveness of the training initiative at risk, resulting in wasted time, energy and money.

| Owners | Interfaces | |||||

|---|---|---|---|---|---|---|

| Maintenance/Engineering | Purchasing / Warehouse / Parts Inventory | Human Resources | Production | Safety and Health (S&H) | Information Technology (IT) | |

| Management | Plant director, operations manager, maintenance manager | Plant director / operations manager | HR director | Operations / production manager | Plant director / operations manager | IT manager |

| Coordinators, Supervisors and Group Leaders | Planning and scheduling, field engineering, maintenance supervisors | Procurement manager | HR advisor | Production supervisors | S&H manager / supervisor | IT support |

| Plant and Field Personnel | Predictive engineers / technicians, lube techs, mechanics | Purchasing clerk | Operators | Inspectors | ||

Involved Personnel

The initial step in constructing a good training plan is to determine if the training is for a specific project, part of a broader skill developmental plan or a combination of both. Let’s consider an initiative that covers both a specific project and personnel skill development, which is the most complete scenario.

If the decision is made to form a taskforce for implementing best practices within a certain amount of time, it will be useful to identify the personnel involved and the ways in which they will be involved. Questions to ask include will these individuals make strategic decisions on this project, will they need a general understanding or specific technical knowledge, what is the specific technical knowledge needed and will they execute routines, making hands-on training beneficial. These questions should be asked not only for individuals but also for groups with similar functions. Once the questions have been answered, a table for the involved team can be created as shown below.

Training Needs

The next step is to define what each person should know about the project’s objectives and scope, the necessary technical knowledge, and the learning and behavioral needs based on the existing gaps between the current qualification level and the new qualification that is required. Also, determine if the learning needs are basic, general knowledge or advanced. At this point, the learning requirements should be described in great detail.

If there are career-development requirements, now is the time to integrate them into the master training plan. Be sure to verify that the job description and career-development plan are consistent, clear, specific and updated with the learning and developmental objectives. If more than one skill level is required for a specific function, the training requirements should be clearly defined according to the progression of skill competencies.

Another question that should be asked is who needs to be aware of this project and its training requirements in order to support it. A good cultural alignment within the organization is fundamentally important.

In this table, three groups of participants are categorized according to their degree of participation in the project. Project owners are displayed in purple, people/functions involved in the project are in yellow, and individuals who must be made aware of the project to provide support are shown in blue.

Finally, the project leader should have a clear understanding of the training and qualification options that are available and suitable for the project. Research internal training resources as well as options in the marketplace. When required, a partnership with a specialized company that provides an array of training services may be helpful.

After this step, a second table can be created to identify the communication/alignment requirements along with the training needs for each individual and the set timeframe. An example is shown below. In some cases it may be important to include external contractors or outsourcing companies that may be affected by the scope of the project.

Training Plan Design

With a clear number of participants for each training or awareness session, you are now ready to define specific aspects of the training plan. This can be accomplished by answering the following questions:

- How will the training be delivered (in the classroom, online, self-study, on the job or a combination)?

- Will a modular or full program be delivered?

- What is the timeframe to complete the plan?

- How will the learning be assessed (in the classroom, in the field or both)?

- What resources will be needed (considering the budget, location and logistics)?

- Which performance indicators will be used (number of participants per class, percentage of approved, man-hours of training, etc.)?

| Maintenance/Engineering | Purchasing | Human Resources | Production | Safety and Health | |

|---|---|---|---|---|---|

| Managerial Opportunity Awareness | Plant director; operations manager; maintenance manager; project leader | Procurement Manager | HR Director | Procurement manager | Environmental Health and Safety (EHS) Manager |

| General Awareness | HR advisor | Production supervisors | |||

| Introduction to Machinery Lubrication and Lubricant Storage and Handling | Planning and scheduling | Purchasing clerk; warehouse personnel | EHS engineers and inspectors | ||

| Machinery Lubrication | Plant and field engineering; maintenance supervisors | ||||

| Introduction to Machinery Lubrication and Best Field Practices | Lube techs; mechanics; millwrights | Operators | |||

| Oil Analysis | Condition-based maintenance technicians |

Plan Execution

Once the budget has been approved and the necessary resources identified and aligned with the involved personnel, it is time to execute the plan. Participants should be notified in advance. Conduct an initial general awareness session to explain the program’s goals, content and timeframe. This will dissipate doubts and concerns while motivating the stakeholders to participate and support the program. Emphasize why the program is being implemented as well as the benefits for the individuals involved. Rewarding participation with certificates and a symbolic gift of the new status may help to create a positive environment.

Effective Implementation Considerations

When implementing a training solution, you need to look beyond just the knowledge, skills and abilities that are impacted. Many times the success or failure of a training program is not realized until the classes are over and the trainers are long gone. The learning objectives and outcome of the training are typically measured in terms of comprehension of the critical knowledge or skills transferred to the employee. However, a key facet of an effective implementation unfortunately is overlooked and many times results in little change and improvement. This important ingredient is the employee’s willingness or motivation. Will the team willingly implement the new skills and knowledge on the job? If the answer is no, then you must investigate the reasons why.

- How would your team describe the purpose of the training?

- How would they rank the importance of bringing this new knowledge back to their tasks?

- How has the expectation of compliance been communicated and how it will be measured?

- How has the team been included in the needs analysis?

Answers to these questions will give an indication of how well the training will be embraced or rejected. While the training provides knowledge and should impact skills, it requires a change in behavior.

In the next issue of Machinery Lubrication, this discussion on implementing a training plan will be continued with an examination of how organizational culture influences training effectiveness.

Training Feedback and Competency

The effectiveness of the training may be assessed using a variety of methods. One simple way is with a course evaluation provided by the participant. This can be used to express the degree of satisfaction with the training, its usefulness and improvement opportunities.

Another approach is to give an exam on the topics presented in the training. The exam could be conducted before and after the training to compare the learning acquired, and may include case studies and exercises. This can be an excellent tool to measure how much information was retained at the end of the training.

The table above offers an example of the training needs of individuals involved in a lubrication excellence program.

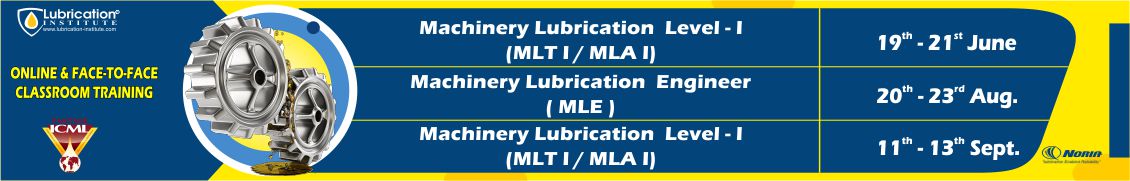

A certification exam provided by a recognized organization like the International Council for Machinery Lubrication (ICML) can be very beneficial. This will motivate and demand a greater commitment from participants as a result of the new status achieved. It can even be used for career development.

The new knowledge or skills should also be verified in the field to ensure procedures are being followed properly. Not only should the new practices be confirmed, but also whether the objectives or improvements have been achieved.

Key performance indicators can be implemented to track the program’s development and success. These might include the average result and the number of certified professionals.

A successful plan demands a thorough understanding of the training needs based on the organization’s objectives. Planning, budgeting and consistent follow-up will also be necessary. While an investment of time and energy will be required, the plan will pay off with better performance, motivation and ultimately improved plant reliability. Take the next step. Learn how Noria can help transform your lubrication program.