New Test Method for Lubricant Biodegradability

Dr. Martin Völtz

Following criticism of the Coordinating European Council’s well-known biodegradability test (CEC-L-33-A-93) for its use of hazardous solvents, and with alternative tests not designed for testing lubricants, a technical development group (TDG-L-103) was formed to establish a replacement test method. After 3½ years, a new biodegradability test procedure has been developed, thoroughly tested and approved. It essentially measures the loss of oil and oil-soluble metabolites over 21 days in a nature-like aqueous environment.

Before presenting the new test method, an understanding of biodegradation may be useful.

Biodegradation

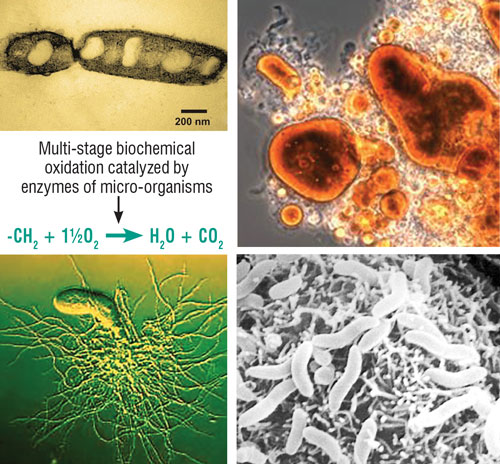

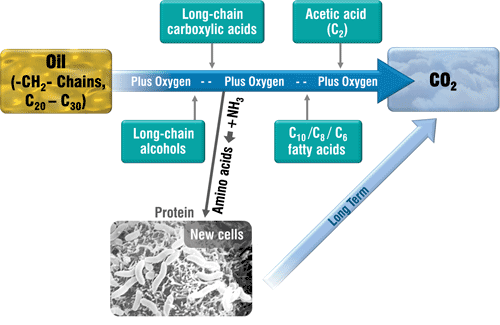

Biodegradation of organic material (natural or synthetic hydrocarbon compounds) is actually biochemical oxidation. It is initiated and performed by the enzymes of micro-organisms such as algae and microfungi. Although similar to combustion, this biochemical process is much longer, comprising several small bio-oxidation steps via long-chain alcohols and carboxylic acids, as well as shorter chain acids down to acetic acid and carbon dioxide. This process delivers energy to the micro-organisms. There is also another side reaction inside these “microbugs” that uses long-chain carboxylic acids for the formation of amino acids and proteins. This reaction makes the micro-organisms grow in size and number.

When oil or other organic material is spilled into natural water containing the usual micro-organisms, the initial speed of biodegradation is very slow, as not all “bugs” present will accept this material as “food.” Those that do will eat and grow in number and size, thus producing a faster biodegradation speed until this food (the added substrate) is fully consumed.

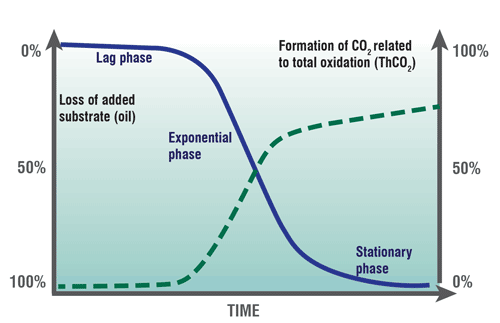

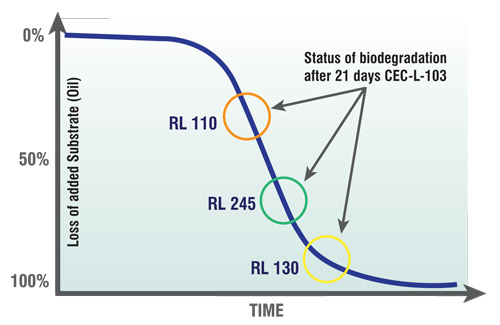

The resulting degradation/time curve of any organic material usually has three stages: the lag (or adaptation) phase, the degradation (or exponential) phase and the stationary phase, where the new biomass will die away if no additional food is added. This type of degradation curve is found whenever the concentration of added organic material is observed. However, when the resulting carbon dioxide is measured, the shape will be somewhat different due to the side reaction into proteins and the time-consuming dying-off process of the biomass produced. This should be noted when comparing the results of oil removal tests with other methods measuring carbon-dioxide production.

The resulting degradation/time curve of any organic material usually has three stages: the lag (or adaptation) phase, the degradation (or exponential) phase and the stationary phase, where the new biomass will die away if no additional food is added. This type of degradation curve is found whenever the concentration of added organic material is observed. However, when the resulting carbon dioxide is measured, the shape will be somewhat different due to the side reaction into proteins and the time-consuming dying-off process of the biomass produced. This should be noted when comparing the results of oil removal tests with other methods measuring carbon-dioxide production.

Test Development

Test Development

The establishment of a new test method for biodegradability began in late 2008 with the formation of the CEC Technical Development Group L-103. It was comprised of three active laboratories and a few industry experts. The group was charged with keeping the basic principles and advantages of the CEC-L-33-A-93 test, such as having a clearly defined oil incorporation procedure, using reference oils, and being suitable and proven for all types and chemistries of oils on the market, especially all types of bio-lubes. In addition, the group was to avoid hazardous solvents, exceed the L-33 test in repeatability and reproducibility, and match the test quality and surveillance criteria of the 2001 guidelines set by the CEC.

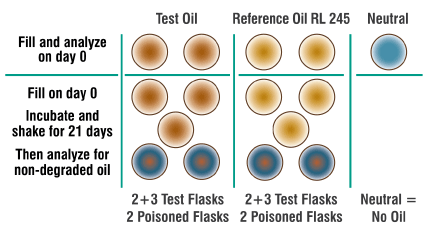

Just like the CEC-L-33-A-93 test, the new test’s basic principle involves preparing a “mineral medium” (similar to natural surface water) that contains some mineral salts and natural micro-organisms. A small volume of oil and a carrier are added to prepare the test flasks, with biocide used for poisoned flasks and no addition made to neutral flasks. The oil contents of these flasks are analyzed and compared on the starting day and after 21 days of incubation in the dark with mild shaking at 25 degrees C. In all, 15 flasks are prepared for each candidate and reference oil - five for instant analysis and 10 for analysis after 21 days of degradation.

In the initial version of the CEC-L-33 test, the carrier material used to introduce the test oil into the aqueous medium was carbon tetra-chloride. Ethylene tetra-chloride or Freon was prescribed after 1993. The same hazardous solvents were also used to extract the non-degraded oil portion for quantitative infrared spectroscopy analysis after three weeks. Excluding the use of such solvents was found to be a significant challenge in the L-103 test development. Eventually, high-temperature gas chromatography was employed for the analytical evaluation of oil concentrations instead of infrared spectroscopy.

In the initial version of the CEC-L-33 test, the carrier material used to introduce the test oil into the aqueous medium was carbon tetra-chloride. Ethylene tetra-chloride or Freon was prescribed after 1993. The same hazardous solvents were also used to extract the non-degraded oil portion for quantitative infrared spectroscopy analysis after three weeks. Excluding the use of such solvents was found to be a significant challenge in the L-103 test development. Eventually, high-temperature gas chromatography was employed for the analytical evaluation of oil concentrations instead of infrared spectroscopy.

Gas Chromatography

Conventional gas chromatography (GC) is a good tool for qualitative and quantitative analysis as well as for producing simulated boiling curves of organic material with a minimum volatility. Lubricants of low and medium viscosity are also suitable for GC analysis but not heavy materials and esters.

High-temperature GC is a development of the last 10 years that has widely overcome these limitations and works well with all types of lubricating oils. Even polymeric components can be analyzed with good precision. Modern high-temperature GC analyzers are highly automated and can offer amazing precision, which enables test flask volumes to be reduced.

Another advantage of GC analysis is that it allows the extraction of residual oil at the end of the test through the use of ordinary, non-toxic hydrocarbon solvents. However, such solvents are not helpful for introducing the oil sample into the aqueous test medium.

Another advantage of GC analysis is that it allows the extraction of residual oil at the end of the test through the use of ordinary, non-toxic hydrocarbon solvents. However, such solvents are not helpful for introducing the oil sample into the aqueous test medium.

An effective biodegradation test must provide equally good dispersion conditions for all types of materials and products. The identification of such a “co-solvent” was an important step in the development of the new test method. This was followed by the exchange of mercury chloride in the abiotic (non-biological) “poisoned flasks” in favor of a mild but efficient organic biocide.

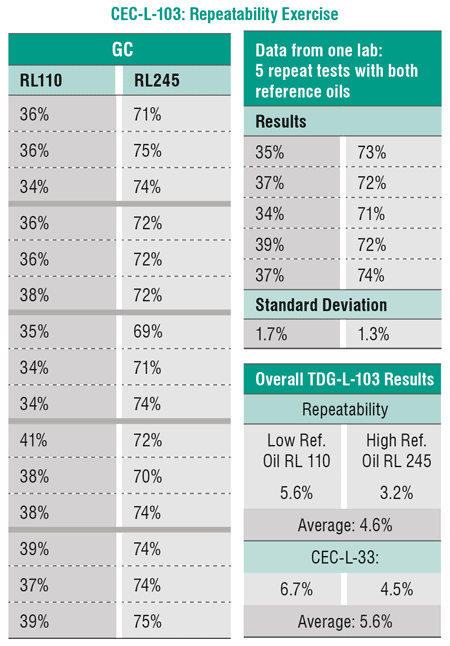

As prescribed for every CEC test-development process, the new procedure had to prove sufficient repeatability and discrimination with two reference oils. In the first phase of development, five repeat tests with two reference oils were conducted in each of the participating laboratories. Very good repeatability was seen in one of the cooperating labs, and clear discrimination of the two tested products was evident in all three laboratories. The average repeatability of all three labs was better than in the CEC-L-33 test.

Round-robin Exercise

The second phase of the CEC test-development process involved the demonstration of the method’s reproducibility in a minimum of five test laboratories. Three additional labs with suitable equipment and skills were located. The active labs in this phase included three independent commercial test labs, one additive supplier, one oil supplier and one governmental lab.

A round-robin exercise was then conducted according to the guidelines set by the CEC with guidance from the Statistical Development Group (SDG). Each lab tested four oils in parallel. One month later, the same oils were tested again using fresh inoculum. This would provide a final judgment on the new test method’s discrimination, repeatability with the same inoculum (batch of micro-organisms), repeatability with another inoculum in the same lab and reproducibility in six different labs using six different inocula.

The average biodegradability results of the six labs were in the range of 35 to 40 percent with mineral base oils and formulations, 70 to 90 percent with synthetic base stocks and oils, and 90 to 100 percent with vegetable oil products. These results showed clear discrimination of high and low biodegradability, with ranges similar to many results associated with the CEC-L-33 test.

The average biodegradability results of the six labs were in the range of 35 to 40 percent with mineral base oils and formulations, 70 to 90 percent with synthetic base stocks and oils, and 90 to 100 percent with vegetable oil products. These results showed clear discrimination of high and low biodegradability, with ranges similar to many results associated with the CEC-L-33 test.

The repeatability of the four samples was calculated at 4 to 7 percent using identical inoculum and 7 to 14 percent using different inocula, with 12 to 19 percent reproducibility. The best figures were seen at high degradation, and the worst at lower degradability. This was not surprising considering the degradation/time curve in which the daily degradation rate is low above 80 percent but high in the 30- to 70-percent range. This led the technical development group in an earlier stage to switch from the “high” reference oil (RL 130) used in the L-33 test with 80- to 90-percent degradation to an alternative synthetic (RL 245) with degradation values near 70 percent.

Nevertheless, the precision data of the new test marked a big step forward in comparison to existing tests, as the reproducibility of the CEC-L-33 test had been 19 to 38 percent in 1991, and the reproducibility of the Organization for Economic Cooperation and Development’s test (OECD-301) using only water-soluble chemicals had been 19 to 40 percent in 1988.

The round-robin exercise made the effect of the individual inocula (bacterial batches) quite obvious. Using two different inocula in the same lab brought the repeatability figures up into the range of the reproducibility. Thus, the relative activity of the micro-organisms was a factor with equal importance as the individual lab and operator.

Summary of the New Lubricant Biodegradability Test Procedure

The new test method (CEC-L-103-12) provides a procedure to evaluate the biodegradability of lubricants in natural water. It is performed in direct comparison with at least one reference oil. Lubricants tested may be base oils or contain usual additives. Base oils can be conventional mineral, hydrogenated/hydrocracked oils, PAOs, synthetics, natural (vegetable) esters or mixtures thereof.

The required hardware for the test includes standard glassware, a shaker tablet and a high-temperature gas-chromatographic column and analyzer. The test medium is natural water from a defined source (comprising a defined level of micro-organisms) enriched with defined nutrient mineral salts.

The test is set up to simulate biodegradation in natural water, i.e., ground water or open rivers, lakes or sea. There is also good correlation with biodegradation in wet soil with the presence of sufficient air/oxygen as well as in biological sewage plants.

The lubricants tested are introduced by pre-dilution with a special solvent. After a 21-day degradation period, the oil content of the test flasks is compared with the original oil concentration and with poisoned (abiotic) reference flasks using oil extraction and a high-temperature GC analyzer. This procedure ensures all original oil and the products of primary biodegradation (long- and medium-chain hydrocarbons, esters, alcohols and fatty acids) are counted as “non-degraded” in the final test evaluation.

Test results provide the percentage of biodegradation over three weeks. For example, a result of 70 percent would indicate that 70 percent of the test material has been degraded biologically over 21 days down to carbon dioxide, protein (cell material) or metabolites that are readily soluble in water and are on a direct biochemical path to ultimate degradation.

Two options were found to minimize or remove this undesired variation through microbial activity. First, each candidate test result must be achieved consecutively with a test of RL 245. In addition, the test result is valid only if the RL result is within the 10-percent range of the last round-robin test’s average. Second, inoculum preconditioning, which involves putting each inoculum into a well-defined environment of standard nutrients before the oil test, was shown to reduce the number of individual species and the individual behavior of the inoculum.

Benefits of the New Test Method

The new test procedure is equally suitable for all types of lubricating oils, base stocks and formulations except water-soluble products. It avoids the use of toxic or harmful chemicals, reduces the overall consumption of chemicals and biomass, and increases test precision. It also offers a good way to simulate the fate of lubricating oil spilled in small quantities within the environment, such as during the operation of chainsaws or two-stroke engines.

Laboratories beginning to perform this new test procedure will need training and experience until they are able to produce valid results. However, the test description contains a number of hurdles and checkpoints that help make insufficient accuracy obvious and grant a high degree of reliability for all valid results.

Of course, there remain several issues that are not sufficiently covered by this or other test methods. For instance, no standard test method exists for simulating biodegradation of severe oil spills in a limited volume of water or soil, as in the cases of accidents with tank cars or mobile hydraulic systems. The main problem in such accidents is oxygen starvation that can lead to severe environmental damage. More research and possibly new test methods may be required to rate products for these real-world conditions.

In addition, during the technical development group’s work, a few tests were conducted with lubricating greases, which produced reasonable results. However, these tests were performed only with low NLGI grades and in a limited number, so the new test procedure cannot be recommended for lubricating greases in general. This may be the subject of further investigation and possibly an optimized test procedure.

Please note that CEC test methods do not define limits for “good” or “acceptable” behavior of candidate oils. This is generally left to those who use CEC test procedures to set specifications, such as the DEKRA product-specific rules guideline for sustainable hydraulic fluids, which was the first specification using the new CEC-L-103 test.