How Particle Ingression Impacts Equipment Reliability

Ingression can be defined as a going in or entering, a right or permission to enter, or a means or place of entering. If you have attended one of Noria’s Fundamentals of Machinery Lubrication courses, I’m sure you understand the importance of reducing, minimizing and eliminating particle ingression. Because of the negative impact particle ingression has on equipment reliability, it is critical to recognize the effects, how particles enter equipment and what you can do to reduce or eliminate ingression.

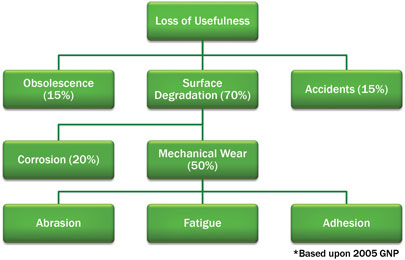

Particle ingression leads to contact fatigue, spalling, pitting, brinelling and cratering. Surface fatigue often develops from denting due to hard or soft particles. This creates a stress riser (berm). Repeated high loading (stress reversals) on berms or particles causes surface fatigue and eventually the formation of pits. This leads to larger pits followed by spalls.

Particles can enter equipment through various means, such as through a process or a mechanical service that is performed after a failure or inspection. Therefore, it is paramount to take all precautions to minimize or eliminate any contaminants (dust, water, etc.) from coming into the equipment.

Most workers must deal with real-world conditions and may need to repair equipment out in the field. In these situations, take time to prep the area prior to opening an inspection door or bearing housing. This would include at the very least cleaning away debris from the inspection door or knocking off dust from overhead beams or adjacent machines.

Often it is the little things that make a big difference. Maintaining a clean area as well as clean tools and performing proper flushing of the equipment to remove any debris left behind can increase machine reliability. You have to give your equipment the best opportunity to perform its intended function, and minimizing or eliminating in-service ingression is essential to achieve this objective.

Ingression can also occur due to process conditions. This usually is the result of damaged seals or breathers and in-service equipment temperature changes, which can produce moisture within the machinery.

3 Types of Particle Ingression

There are three general types of solid particle ingression: built-in, ingested and generated.

Built-in contamination consists of manufacturing debris such as burrs, machining swarf, weld spatter, abrasives, drill turnings, filings and dust. It can also include service debris that occurs when machines are opened for routine repairs and preventive maintenance.

Ingested particle ingression means that particles are coming into the machine and the lubricant under normal operating conditions (from the outside to the inside). These could be process particles (pulp, pulverized coal, ore dust, cement, clays, process chemicals, etc.), atmospheric contaminants (the result of ambient or road conditions near the machine), or combustion debris from internal combustion engines (soot, fly ash, induction air and contaminated fuel).

Generated particle ingression is when the machine makes its own particles. This can occur on internal surfaces through corrosion, mechanical wear, cavitation, exfoliation, etc. The oil also has the ability to break down and form particles (sludge, oxide insolubles, carbonization, coke, etc.).

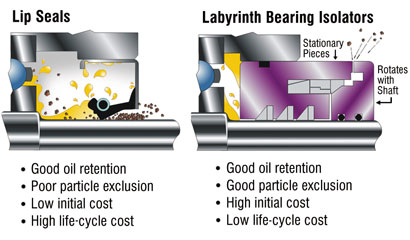

Faulty seals can allow contaminant ingression, which may lead to surface degradation. Machinery inspections should be performed routinely. Repairs, modifications and purchasing improved seals may be necessary to improve equipment reliability.

Keep in mind that not all seals are created equal. A proper assessment of your equipment as it pertains to temperature and the type of lubricant that you are using is crucial. Many times the lubricant and the seal may be incompatible, which can result in oil leaks. Remember, if you observe oil leaking out, there is an opportunity for contaminants to get inside the equipment.

The selection of breathers and monitoring breather condition provide another method of reducing ingression. Whether you are using them to eliminate dirt or water ingression, breathers are imperative for machine health. They must be selected according to the machinery conditions and environment. Frequently, breathers are not monitored properly. Like oil filters, they have an intended purpose and function well; however, once they reach the end of their life cycle, it is important to replace them promptly.

Remember, education is key. Understanding how ingression affects oil and equipment life is critical. Look beyond the obvious. Whether it is a color change of a breather, oil leaking from a seal, or water ingression in the oil, recognizing the effects of ingression can help you act promptly to improve machine reliability.